Tobias Andersson

School of Engineering Science

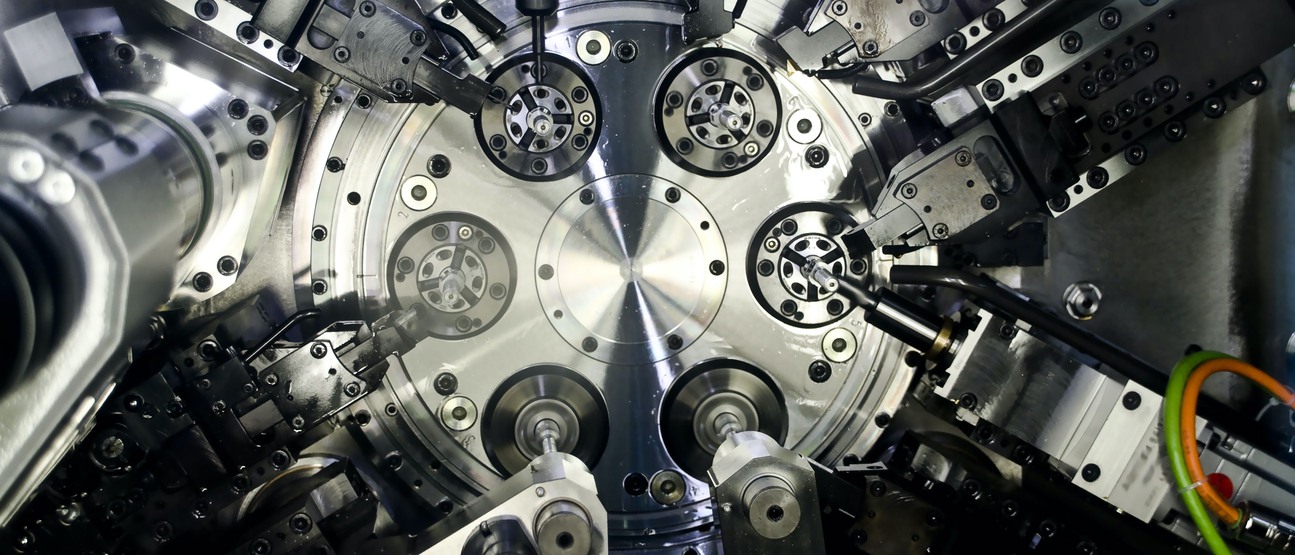

Virtual models continue to develop in the area of machining. The finite element method (FEM) is the dominating method for performing simulation of the cutting process. Much research is conducted to obtain reliable models that can be used to model complex cutting processes in industrial applications.

However, the fixture holding the tool and the machine itself influences the result of the cutting process. Vibrations, heat, etc. that are a result of the cutting process transmits through the fixture and possibly the entire machine and can have a profound effect the surface roughness, part distortion etc.

To overcome the problem with too large models the larger models need to be reduced into smaller models using either the so called Co-sim technique or by using substitute modelling. A lot of research needs to be done in this area and this project aims at studying these techniques further. This will lead to considerably shortened computational times and the ability to model and simulate real world industrial problems with better accuracy.