Kent Salomonsson

School of Engineering Science

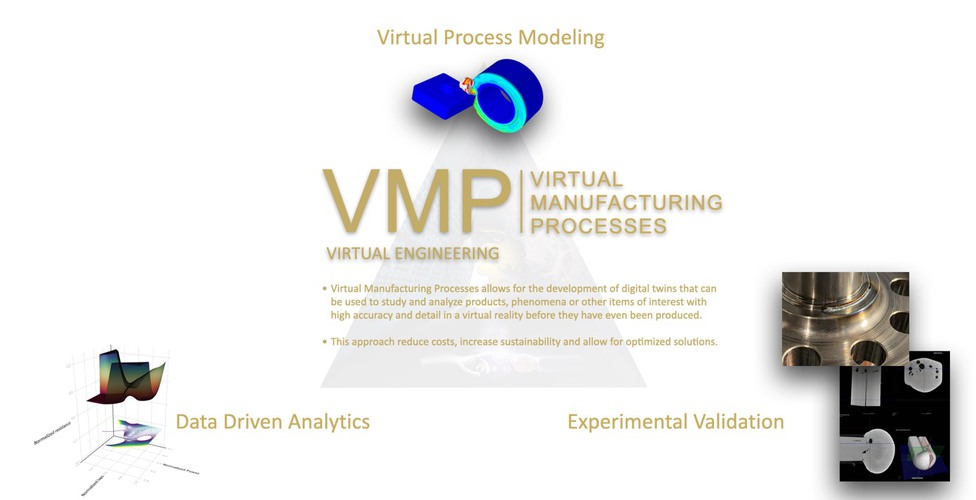

The research within the Virtual Manufacturing Processes (VMP) group is mainly focused on three different, but yet symbiotic fields of research, namely Data Driven Analytics (DDA), Virtual Process Modeling (VPM) and Experimental Validation (EV).

Numerical modeling techniques, such as the finite element method, are predominately used within the field of engineering to build and analyze physical phenomena as digital twins. As such, the research group develop numerical models for problems in solid mechanics, fluid mechanics, acoustics, electromagnetics and lately within biomechanics.

Over past three years, the VMP research group has focused on machining technology and has built competence during this time within this area in terms of virtualization but also in terms of experimental validation. Recently, due to the strong connection with industry in the local region and the global transformation to electrification, the VMP group has added laser welding and injection molding to the research focus areas.

The research focus areas in the group are seen as applied problems that fuel the fields of research within the group. The research group is also involved in several other research projects at the University of Skövde, thus collaborating with other cross disciplinary research groups.