Rohollah Ghasemi

School of Engineering Science

The manufacturing industry worldwide has great demands on itself to create sustainable products and reduce its environmental impact, demands that force the industry to move its production from traditional methods to new efficient processes. For six years, the QWELD project will develop methods for quality assurance and optimization of laser and ultrasonically welded components.

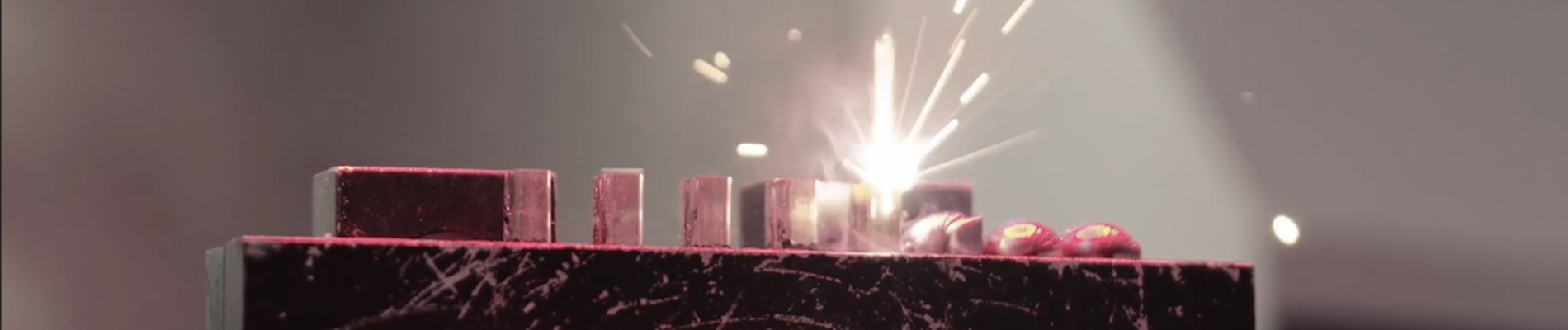

Today, there are several different types of welding methods in the manufacturing industry. In the QWELD project, laser and ultrasonic welding are the focus. Techniques that are on the rise and that will be able to replace traditional welding. Laser and ultrasonic welding have greater safety and precision, they are also faster and use only a fraction of the energy required in traditional welding. Today, these welding methods are used, among other things, in the production of electric drivelines.

The project will work with the latest virtual technologies to achieve the project goal. For example, QWELD will:

The project will help the industry gain an increased understanding of the mechanisms behind welding and how manufacturing companies, by taking advantage of virtual technologies and machine learning, can influence the quality of laser and ultrasonically welded components. Knowledge that contributes to the digital transition, and a continued competitive industry.

The project is funded by the innovation program Produktion2030, a joint venture by Vinnova, Formas and the Swedish Energy Agency.

The goal of the program Produktion2030 is to increase the Swedish manufacturing industry's global competitiveness by building a sustainable and resilient manufacturing industry. With the Swedish national sustainability goal of becoming fossil-free by 2045, it is natural and crucial for universities, research institutes and companies to build interdisciplinary research groups to develop new and sustainable manufacturing techniques, for example for electric vehicles.