Anna Syberfeldt

School of Engineering Science

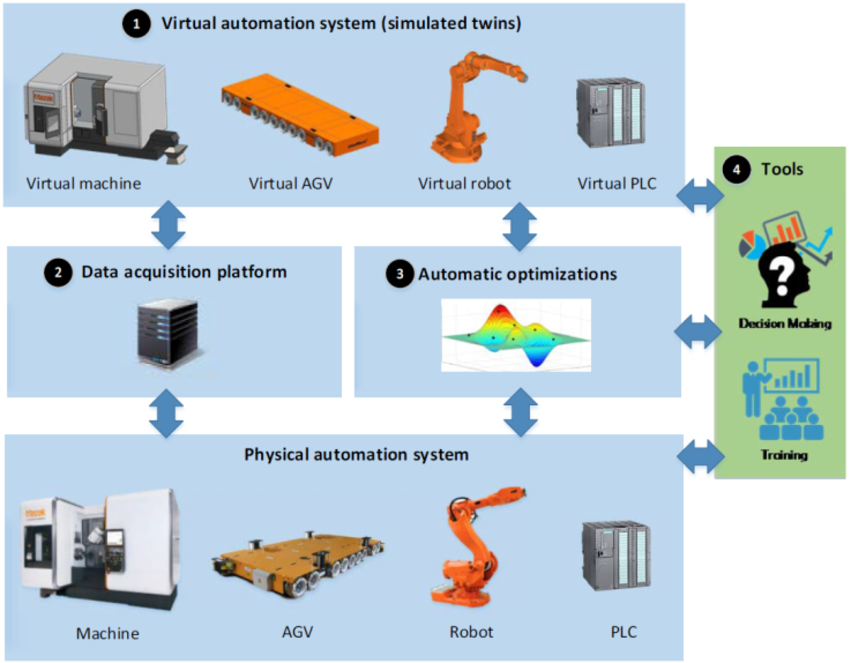

With Industry 4.0 comes a technological evolution towards cyber-physical systems and a paradigm shift from centralized to decentralized production. This paradigm shift will change production. Our goal within the TWIN project is to develop a holistic solution for integrating a simulated twin of an automation system that covers the system’s entire life cycle. Such a solution will help companies stay competitive in a global and rapidly changing market and meet the challenges accompanying the fourth industrial revolution, such as mass-customization and short product life cycles.

With the kind of holistic solution developed in TWIN, virtual commissioning of the automation system could be undertaken in all steps of its life cycle making it easier for companies to implement flexible and intelligent automation systems. Based on the simulated twin, companies could easily and cost-effectively evaluate modifications, make improvements, and train operators when changes in the production setup occur due to mass-customization or new products being introduced.

Increased productivity and quality of automation solutions throughout the entire life cycle. For example by reducing production stop times, reducing failure risk when implementing system modifications and by increasing staff knowledge.

Minimal costs and lead times in the conceptual and development phases.

Enabling the concept of "batch size of one" (mass customization/high product mix) in practice through supporting minimal costs and minimal lead times when changing the production setup.

Easy to make improvements in a working system, test modifications, debug system failures, etc., without disrupting the production system.

Efficient training of maintenance staff and operators.

Figure: Basically, the solution consists of four parts: ❶ a simulated automation twin of the physical automation environment, ❷ an IT platform for automated data acquisition, ❸ a simulation-based optimization based on the digital twin, ❹ tools for training staffs and making informed decisions based on the simulations.

Figure: Basically, the solution consists of four parts: ❶ a simulated automation twin of the physical automation environment, ❷ an IT platform for automated data acquisition, ❸ a simulation-based optimization based on the digital twin, ❹ tools for training staffs and making informed decisions based on the simulations.