Vascular diseases (i.e. conditions affecting our blood vessels) affect millions of people worldwide. The waiting time for a donor organ can be long. For the past two years, the University of Skövde has been collaborating with the companies Verigraft AB and Xvivo AB in order to study the production of individually adapted vascular transplants that could reduce the waiting time for donor organs, and the project is showing good results.

The treatment that is currently available for vascular diseases with regard to transplantation involves using the patient’s own blood vessels to transplant to the damaged area. The treatment often causes complications, and there is also a general shortage of organs for donation.

Showing promising results

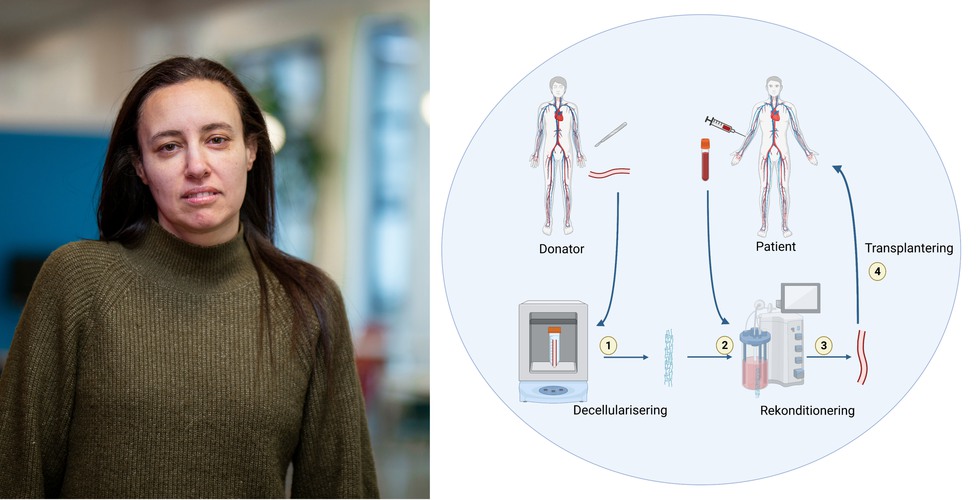

As an alternative, the TransTissue project has studied the use of donated blood vessels. The production of blood vessels with this method involves removing all the cells from a donated blood vessel so that only the structure that holds the cells together remains, still intact and functional. The patient’s own blood is then added to the structure in order to supply the vein with the recipient patient’s own proteins.

“The technology has previously shown promising results in trials on pigs, and trials will soon begin using human patients. In this project, we have studied all the proteins that are present in veins produced in this way. The experiments have involved veins from pigs and humans being injected with pig and human blood, respectively, in order to compare the two systems and to predict whether transplantation in humans is likely to work as well as in the experiments previously performed on pigs”, explains Nidal Ghosheh at the University of Skövde.

Faster treatment for patients waiting for donor organs

The pigs that received transplanted manufactured blood vessels in a previous study have shown no signs of transplant rejection, which bodes well for the future.

“Our results show that the adaptation of the vein already begins in the test tube. This project has given us a better understanding of this blood vessel manufacturing process. Further studies and improvements of tissues that are manufactured in vitro would result in faster treatment options for patients who are waiting for a donor organ. Because the preclinical studies have shown such promising results, clinical trials will soon be conducted”, says Nidal Ghosheh.

Collaboration provides social benefits and strengthens the University’s programmes

The TransTissue project has also helped the University to expand the network of researchers, by bringing in two new collaborative partners. The project has also generated new analytical methods that can be used in education and research. The two companies that are now collaborating with the University of Skövde are expecting the project to result in major benefits:

“The University of Skövde has a great deal of expertise in areas that we do not, such as in bioinformatics and the handling of large amounts of data. This gives us the opportunity to conduct cutting-edge research in this field in a way we would not otherwise be able to. First and foremost, this project has generated a large amount of high-quality research data. This strengthens our knowledge of the products we are developing, gives us the opportunity to refine our production processes, and provides us with a favourable situation for the development of future products”, says Dr. Petter Björquist, who is the CEO of Verigraft AB.