There is a paradigm shift happening within the manufacturing industry, going from a technology-centric approach (Industry 4.0) to a more holistic, human-centric and sustainable approach (Industry 5.0). Researchers at the University of Skövde have been granted 12 million SEK by the Knowledge Foundation to support companies in transitioning from Industry 4.0 to Industry 5.0.

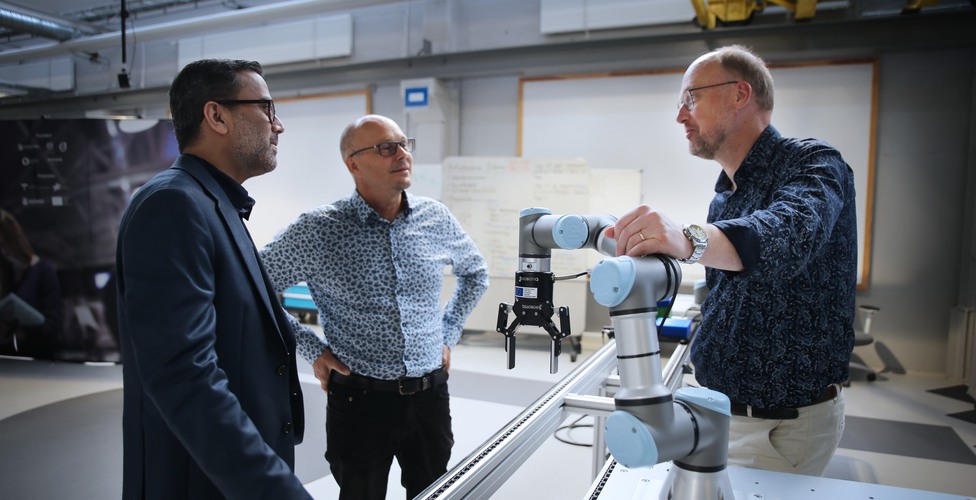

Magnus Holm, Sunith Bandaru and Dan Högberg from the LITMUS project.

Magnus Holm, Sunith Bandaru and Dan Högberg from the LITMUS project.

– This new era of industrial revolution is not about introducing new technologies, but rather about leveraging existing ones to advance towards a more human-centric and sustainable development, says Sunith Bandaru, Professor of Production Engineering and project leader of the LITMUS project.

A new era of industrial revolution

LITMUS (Leveraging Industry 4.0 Technologies for Human-Centric Sustainable Production) is a four-year project (2024-2028) led by the University of Skövde. The overall goal is to support manufacturing companies improve economic, social, and environmental sustainability of their production operations. Just like a litmus test, the project will demonstrate how to effectively manage the transition of companies from Industry 4.0 to Industry 5.0. The project will be executed in close collaboration with the manufacturing industry.

– We have excellent collaboration with both large, medium-sized and small industrial companies and a good understanding of their challenges. As a University we seem to have found a niche that we are good at and where companies want to collaborate. Together we will address the areas of ergonomics, manufacturing productivity, and resource efficiency using simulations, optimizations, and advanced data analytics, says Dan Högberg, Professor of Product Design Engineering.

The LITMUS project will support companies in transitioning from Industry 4.0 to Industry 5.0.

The LITMUS project will support companies in transitioning from Industry 4.0 to Industry 5.0.

– The overall aim of the LITMUS project aligns very well with the goals and needs of all manufacturing companies today. Technology is a more of a tool, and not a goal in itself, as it was in Industry 4.0, says Magnus Holm, Senior Lecturer in Automation Engineering.

A strong request from the EU

Many manufacturing companies in Sweden have quickly adopted the technologies of Industry 4.0 within their businesses, but as the world faces mounting concerns related to the environment, climate, and resources, along with drastic events such as pandemics, wars, and economic crises, the EU requires a more holistic approach to industrial digitalisation.

Industry 5.0 emphasizes a human-centric and sustainable development focus, integrating advanced digital technologies with a strong commitment to enhancing human well-being, social equity, and responsible consumption in the manufacturing sector. So, what can the practical impacts of Industry 5.0 be?

– For instance, ergonomic improvements can lead to better working conditions and reduced injury rates, while advanced simulations can optimise workflows to minimize physical strain on workers. Additionally, leveraging data to create personalised and adaptive work environments can boost both productivity and job satisfaction. By focusing on these aspects, Industry 5.0 not only aims to advance technological capabilities but also to significantly improve the well-being and engagement of the workforce, says Sunith Bandaru.

Skövde: A knowledge-hub in Virtual Engineering

The LITMUS project will be coordinated from the School of Engineering Science at University of Skövde. In the project, the University collaborates with Aurobay, IDC West Sweden, Industrial Path Solutions, Scania, Viscando, Volvo Construction Equipment and Volvo Group Truck Operations, and is funded by The Knowledge Foundation.

– We have a long experience of past and ongoing projects within our Virtual Engineering research environment at the University of Skövde, and this project is a continuation of this legacy. I am convinced that the results from LITMUS will bring new perspectives to support the digitalisation and transition of the Swedish manufacturing industry towards Industry 5.0, says Sunith Bandaru.